Switchboards

Projects, Upgrades, Modifications, Fault Finding

Switchboards

We can provide complete overhaul refurbishment to fault-finding control issues to regular service maintenance of the mechanical switchboard.

Upgrades, Compliance with Australian Standards, Relocations, Modifications, and additional sub-panels to the switchboard.

Switchboard Projects

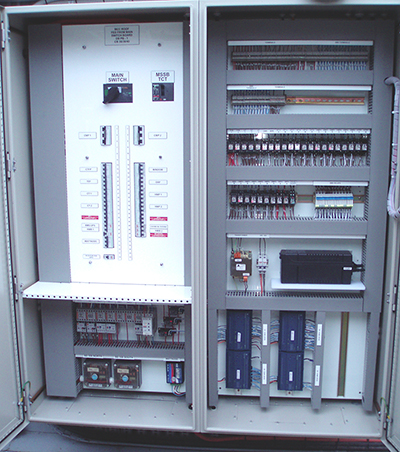

Include in a single Package a Switchboard upgrade or new installation with the Mechanical Electrical installation, Variable speed drives, Building Management System and periphery components, removing the “grey areas” in project management and coordination.

Compliant with relevant Australian Standards and to your consultant’s specifications. All Documentation, including engineering, design, datasheets for the components, and design specifications of the board. In line with the functional specifications of the Electrical mechanical installation and the BMS installation.

Technicians are trained and experienced

Switchboard Maintenance

What’s involved in the maintenance of a switchboard?

- Check operations

- Check Phase loads

- Check Fuses

- Check Schematics

- Check therm-graphic imaging (under load)

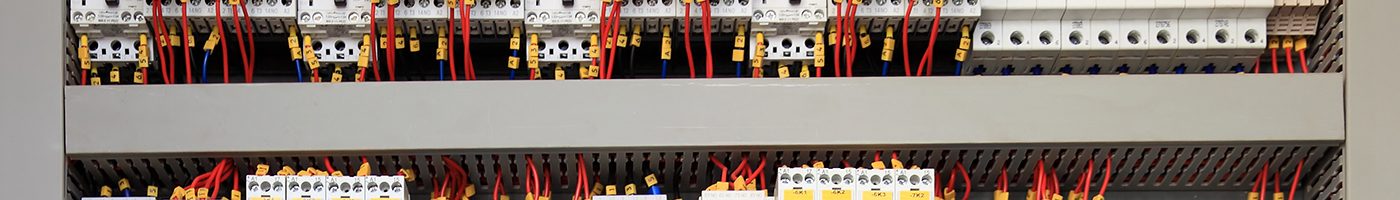

- Check terminals

- Check secure mounting of equipment

All these items are essential checks; one of the most important aspects of these checks is checking the terminals are tight.

The reason for this is they regularly can become loose. Remember the electrical current is going through these terminals at 50 Hertz that is causing a vibration of 50 hertz in the terminal. They do become loose, creating heat spots, then arcing, then eventually a fire. Checking the terminals and/or a thermos-graphic scan can save you thousands.

Thermos-graphic Imaging Scan

A thermos-graphic scan of the board under load will see hot spots. These hot spot are created for a number of reason, not the least of which is loose terminals.

Fault Finding / Repairs

On-site repairs, upgrades, and refurbishments.

From small car park fan control panels to central motor control switchboards serving multiple chillers, chilled water pumps, air handling units and more.

Age is no Barrier

The age of the switchboard is no concern; it is treated like any other.

Documentation will likely be out of date; we can bring schematics back to date and ensure compliance in the switchboard.

Schematics

Older switchboards may require Schematics to be created or part thereof.

Tracing out circuits and creating schematics can be a time consuming process, but worthwhile if the intent is to keep the building or tenancy for the long term or if modifications are being considered for energy management opportunities in the existing installation.

We work on obsolete equipment to repair, fault find and refurbish

Every Situation is different; it could be more economical to rebuild the switchboard and take advantage of the new warranty opportunity instead of working out “what is what” with the existing installation.

Electrical Energy Metering

Installing “split core” current transformers for connection to an energy meter (lon Work, BACnet, Modbus) for stand-alone applications or integration into a Building Management system is relatively straightforward. The amount of room available around the cable for the Physical installation of the transformer is typically the only concern with the installation. The cable sheath should be PVC or similar (the Old MIMS cable or Pyro, being a copper sheath, won’t work, and an alternative location or strategy will need to be developed) to ensure an accurate measurement. Calibration with a third-party amp Meter ensures the meters are reading correctly. (voltage connections are also necessary).

BMS Controllers Installation into Existing Switchboards

Saving you money, time and inconvenience, there is often the opportunity to remove old control equipment from an existing switchboard, making enough room for the new controllers to be supplied, installed and commissioned on-site, in situ.