High-Level Interface

- Home

- Technical Services | Fire | Electrical | HVAC

- Building Automation

- High-Level Interface

High-Level Interface

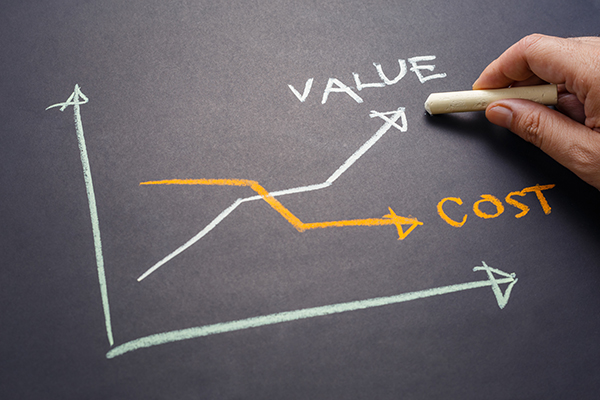

The BMS (Building Management System) in your building is very likely to have the capability to take advantage of the High-Level Interface cards in a plethora of fixed assets. The hidden potential in optimising these devices is enormous and cost-effective, with a return on investment typically in less than 12 months.

If you are a building or facility manager who hasn’t optimised the high-level interfaces in your equipment, you could be costing your client a significant amount in energy and maintenance costs.

What is a HLI

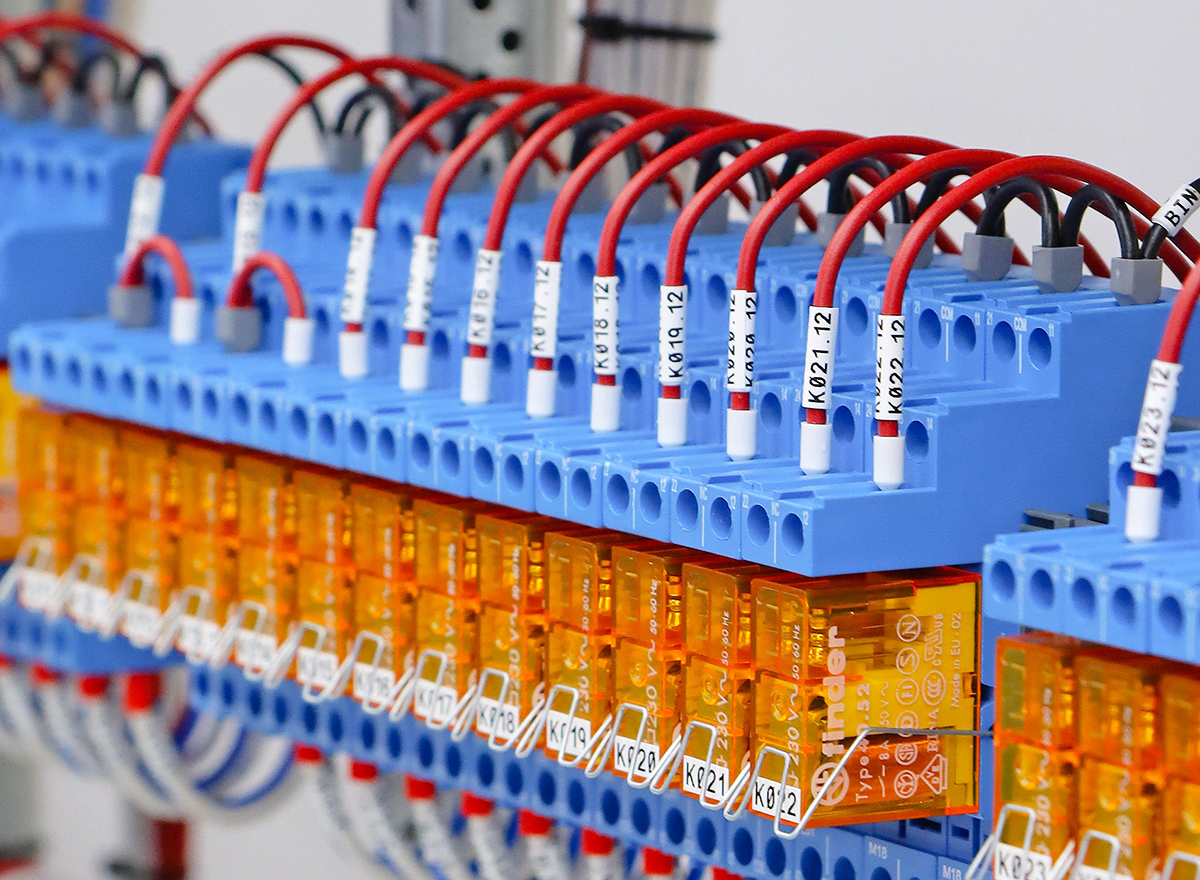

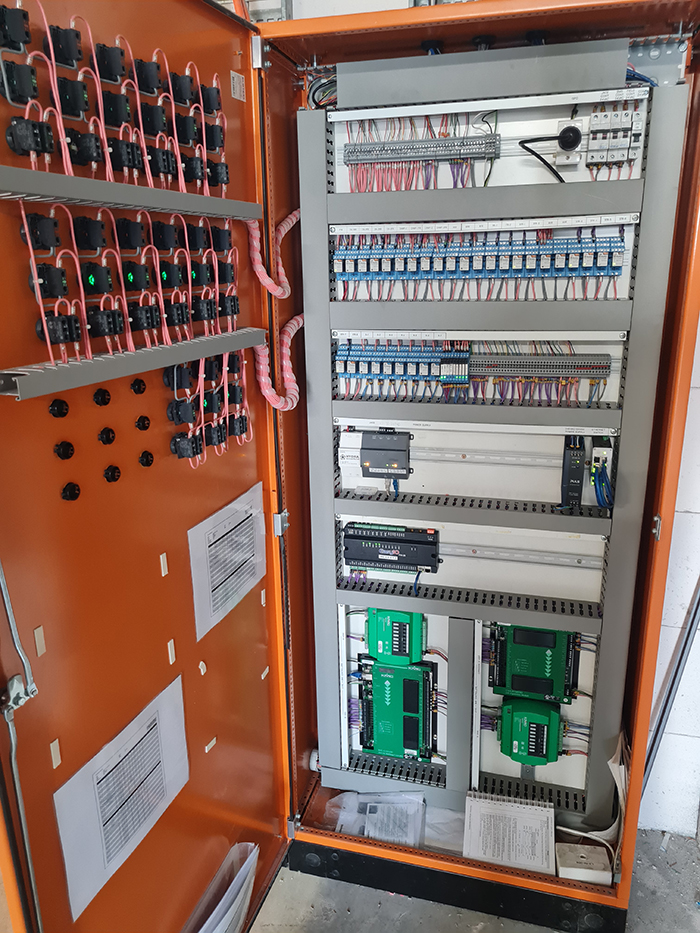

The High-level Interface is typically a Small printed Circuit board fitted to a fixed asset to provide a data link. It is like a transducer between the O.E.M. proprietary system and the open protocol or systems world

How Does it Work

Typically, the Printed circuit board is already available in the equipment and configured by the O.E.M. Three wires and connected it back to your Building Management Control System. Map or configure the points and it’s done.

How Does it Connect

Three wires are connected back to your Automation system, select the relevant open protocols and the device should start talking. then in Spfat where the available points are “mapped” across. This straight forward and not a big-time consumer for the BMS technician.

Why Is it “Cost Effective”

The High-level Interface uses a data connection. This means information that is sent (or received) is faster and more reliable. The Alternative is to use a low-level interface, which requires a greater number of cables and connections, one pair for each point.

What is “Low-level”

A Low-level interface is relay logic and analogue inputs and outputs using volt or current signals. This requires additional controllers, additional cables and additional programming.

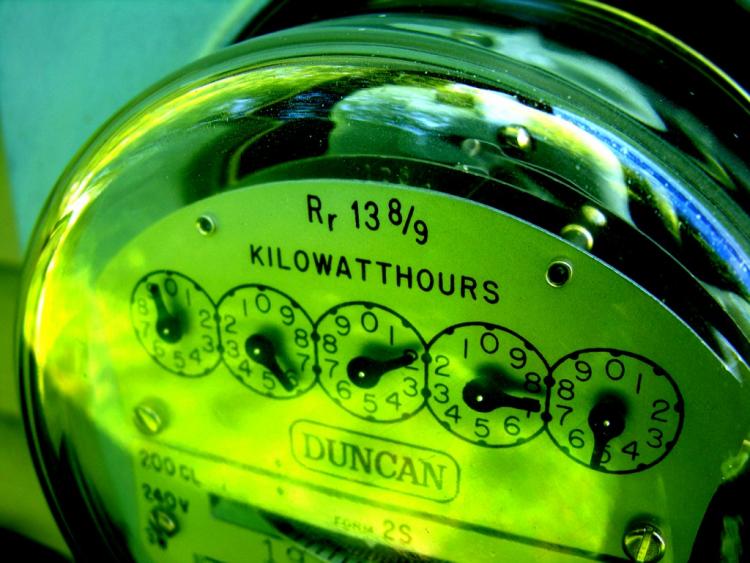

Energy Management

Most high-level interface systems are pre-configured with energy data parameters that can be exported to the BMS. This means the operator can track this data in a trend log and/or create signals based on a condition to switch something off. Hence, an energy management system begins to take shape…..in software.

Interface Between Assets

The High-level Interface uses a data connection. This means information that is sent (or received) can be sent across devices. You can link the fire system to the elevator system, the chiller, and the emergency lights (IoT) via the HLI systems.

Installation Savings

Put simply the High-Level Interface is fewer cables and fewer connections. The programming time is comparable to inputs and outputs which are low-level. It’s a no brainer.

Future Proofing

The Return on Investment is not just in the initial set-up. New energy management strategies are born every day. New ideas to monitor and preserve the life of your assets are born every day. By optimising and maximizing the features in the High-Level interface, you have a future-proof opportunity.

Can We Help You Further

Links

Contact Us

Sydney

02 9091 8009

Melbourne

03 9982 4414

National (24/7, 365 days)

1300 920 752

Can we Help you Today

info@forteas.com.au

1300 920 752

0439 402 599

Sydney, Melbourne & Canberra

Greater Sydney, Parramatta, Penrith, Blue Mountains, Central Coast, Newcastle, Wollongong, Dubbo, and others

greater Canberra

Greater Melbourne, Casey, Stonnington, Ballarat, Wodonga, and others