Cooling Towers | RMP

Risk Management Plan

Back Ground Information

✳ The Air Conditoning System in your building removes the heat in your office to keep you cool in summer.

When the air-conditoning system does this, the heat needs to be removed from the A/C. The cooling towers are the last stage in this process and are designed to remove the heat from the Air conditioning system and dispel it atmosphere.

✳ The water in a cooling tower system will typically run at around 25 degrees to 45 degrees, subject to the load on the air-conditioning system. Legionella thirves in this temperature range.

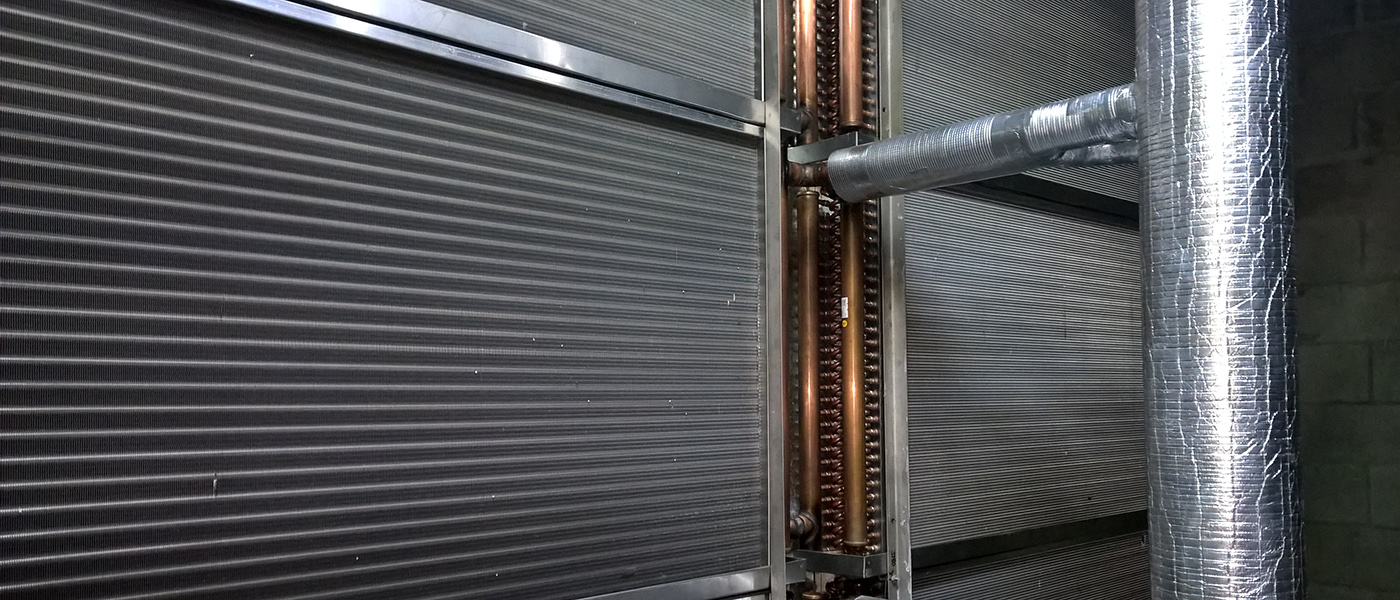

The image show us three condenser water pumps which serve the air conditioning system to dispel the heat via the cooling towers. (not shown) The cooling towers task is to cool this condenser water system (that is, remove the heat to atmosphere) ready for the return leg for reuse in the chillers.

Legionella Disease

Back Ground Information

✳ Water temperatures between 20 and 45 degrees Celsius provide the ideal range to allow the bacteria to grow and multiply. If Legionella are permitted to remain in water at this temperature, the whole water system concerned is at risk of infection, and this can occur very quickly. This puts anyone who uses the water system at potential risk from Legionnaires’ disease. See legionellacontrol.com

Cooling Tower Condenser Water Testing

Back Ground Information

✳ The condenser water is sampled at regular intervals and in line with the chemical dosing company. In the Image we can see a simple pot taken of the water in this particular Cooling Tower.

✳ Why is the Management of the condenser water in the cooling tower system so important?

✳ Why do we need a risk Management Plan?

✳ It is about public health. Although the cooling tower might be on top of the building, way above street level, the fine droplets of water can and do find their way to the street where people can become infected simply by inhaling the fine airborne droplets. you would never know.

✳ The legionnaire’s disease carried in the droplets of fine water which you have just inhaled, may cause Legionnaires disease which can be potentially life-threatening and has taken lives.

✳ Testing just be completed every Month

✳ There are differing requirements between the states, for example Victoria requires an annual Audit of the RMP for your cooling towers. Check with your local authorities.

What are your RMP/

Risk Management Plan obligations?

Back Ground Information

✳ There are Six key Requirements as part of your RMP obligations

1️⃣ Assessing the risk of Legionellat contamination and preparing the Rosk management Plan EVERY 5 years

2️⃣ Independent auditing of the compliance with the RMOP and regulations every year

3️⃣ Providing certificates of the RMP completion and Audit completion to local government (Council)

4️⃣ Sampling and Testing for Legionella and heterotrophic colony count every month

5️⃣ Notifying reportable laboratory test result an d/or heterotrophic colony count to the local government authority

6️⃣ Displaying Unique Identification numbers on all cooling Towers

What are your RMP/

Risk Management Plan obligations?

Record Keeping

✳ When your Cooling Tower RMP Auditor visits site to inspect your cooling Towers, they will need to see your documentation.

1️⃣ all maintenance activities undertaken in relation to the system; this includes records of any services, cleans, inspections and repairs to the system

2️⃣ all microbiological test results of samples taken from the system

3️⃣ any approval issued by the Secretary of the department to use a different method of maintenance and testing.

4️⃣ More Details – here

Risk Management Plan / RMP

What Next?

Back Ground Information

✳ We can help you with these regulations,

✳ Create / build you a Risk Management Plan / Cooling Tower RMP,

✳ Provide third party testing and reporting to local government

✳ Manage and maintain relevant cooling tower system upgrades and repairs as required for on going compliance

✳ Supply and install unique identifications for each cooling tower

✳ orgnise registration of cooling towers with Council

✳ Manage and organize the maintenance for regular chemical doesing and third-party monthly testing.

✳ Provide a total and holistic Cooling tower maintenance and compliance regimen

✳ The Regulation requires all cooling water systems

to be managed according to Australian/New Zealand

Standard (AS/NZS) 3666 Part 3 (2011 edition).

✳ More information – here