- Home

- Technical Services | Fire | Electrical | HVAC

- Mechanical Services

- Sustainability in Maintenance

Sustainability in Maintenance

We bring effective sustainability into any maintenance agreement. There are two fundamental disciplines we manage to improve the overall footprint of the environmental effect of our maintenance works.

Waste and Energy.

Firstly is it core to make stakeholders, vendors and employees aware of how a site is managed to reduce environmental impact.

How We Can Help you With Your Sustainability Objectives

First of all, we need to know and understand your business’s sustainability objectives; provide us with your environmental policy statement and other relevant details as part of the initial maintenance agreement scope, and we’ll be able to ensure your objectives are included as part of the maintenance agreement for your approval.

The Maintenance agreement, with the objectives, becomes the control document for the technicians to perform their maintenance works. by having the base maintenance scope based on your company’s environmental policy, it ensures results aligned with your company’s values.

Proactive Maintenance Will Reduce Energy Consumption

Alignment with your company’s values and policies, including safety, develops a system of documentation we can both follow as a united team.

Additionally, this will mean these maintenance sustainability objectives can be converted into a job task that is included in the scope of work the technician uses on-site; hence, the objectives become a physical activity that can be measured and verified.

We have a secure understanding of the NABERS assessment protocols for Energy and Water, which means we can provide information to you when we see opportunities to improve assessments, especially with the Controls and Building Automation System and the mechanical services HVAC equipment.

NABERS Rating

The reduction in energy consumption will have a positive effect on the Nabers rating of your commercial property.

Fundamental maintenance practices such as changing air filters on air handling units in your air conditioning system are simple and cost-effective. Supply air fans don’t have to “work” as hard to pull the air through a dirty filter; the overall efficiency of transferring energy via the cooling coils improves, reducing the load on major equipment such as chillers.

More opportunity is in control of fans, dampers, valves and other peripheral equipment which serves your main mechanical services air conditioning plant.

Ask us more on this topic, including; –

- Building Services Audits

- Controls Audits

- Energy Audits

- HVAC mechanical Services maintenance

- Building Automation

Sustainability in Maintenance Will Make a Difference

The implementation of your preventative maintenance agreement with a sustainability objective will garnish results.

The effects of poor maintenance or the “run to fail” strategy may not show up in the “repair and maintenance” ledger, but it will show up in the energy costs budget.

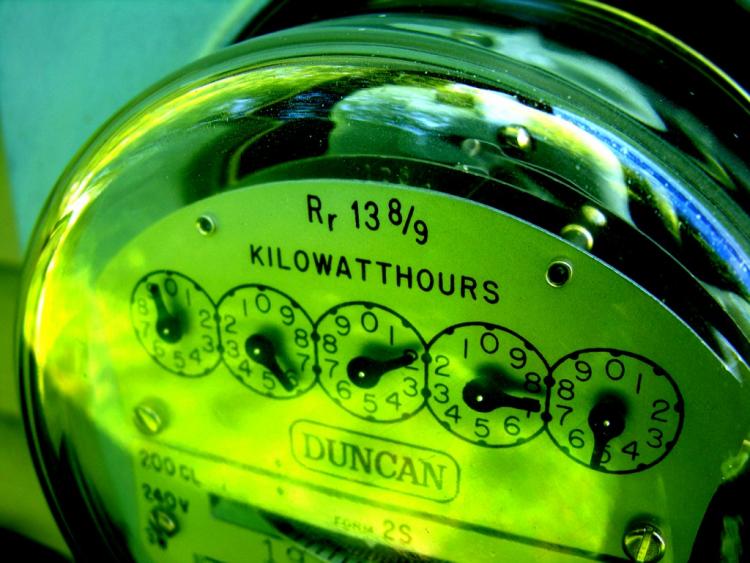

You “can’t have your cake and eat it too”. There is always a cost. With energy costs per kilowatt hour and gas costs increasing, the “run to fail” may cause more costs in other budgets.

Tenant retention statistics may be affected as tenants concerned with continued breakdowns may choose to find new premises.

The indirect costs associated with poor maintenance or “run to fail” strategies include:Ask us more on this topic, including; –

- Higher running costs, energy management

- Indirect costs, such as damage to peripheral equipment or infrastructure

- Reputation costs, including lower tenant retention

- Lower Nabers rating affecting value and reputation

- Rental income with tenants negotiating using poor maintenance as a strategy

- Additional breakdowns and after hour call outs

- “Outgoings” budgets are affected, causing disputes or tenants becoming disgruntled.

Commercial Building Main Plant Maintenance

Here are a few links to other pages which might help your further

Can We Help You Further?

Links

Contact Us

Sydney

02 9091 8009

Melbourne

03 9982 4414

National (24/7, 365 days)

1300 920 752

Can we Help you Today

info@forteas.com.au

1300 920 752

0439 402 599

Sydney, Melbourne & Canberra

Greater Sydney, Parramatta, Penrith, Blue Mountains, Central Coast, Newcastle, Wollongong, Dubbo, and others

greater Canberra

Greater Melbourne, Casey, Stonnington, Ballarat, Wodonga, and others